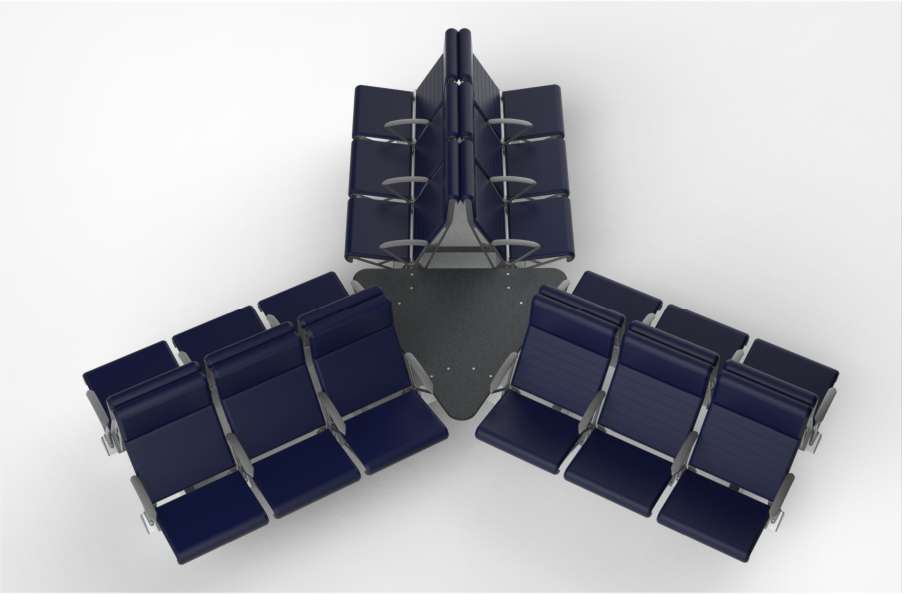

Trax

The most modular seating system.

First designed in 1989 and leading the market ever since, Trax has been continuously developed to suit the evolving requirements for public seating. As OMK’s bestselling seating system, it has been individually configured for use in hundreds of projects worldwide.

Features

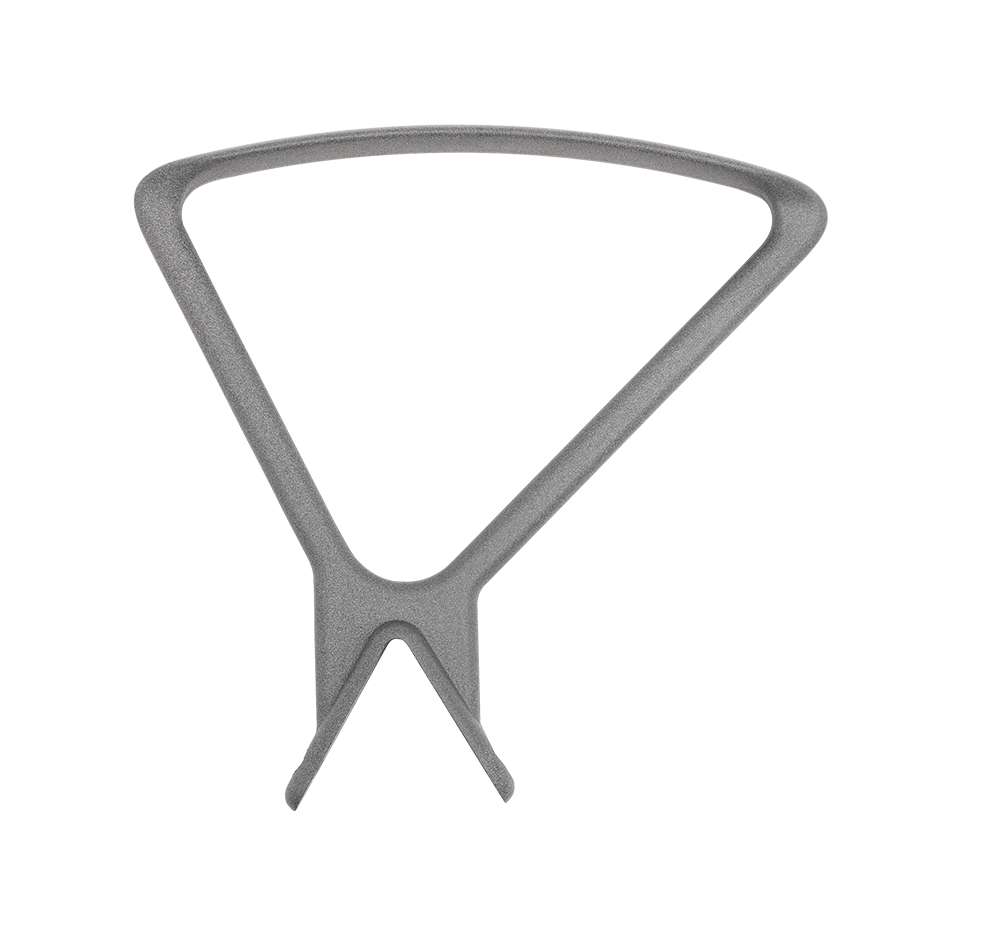

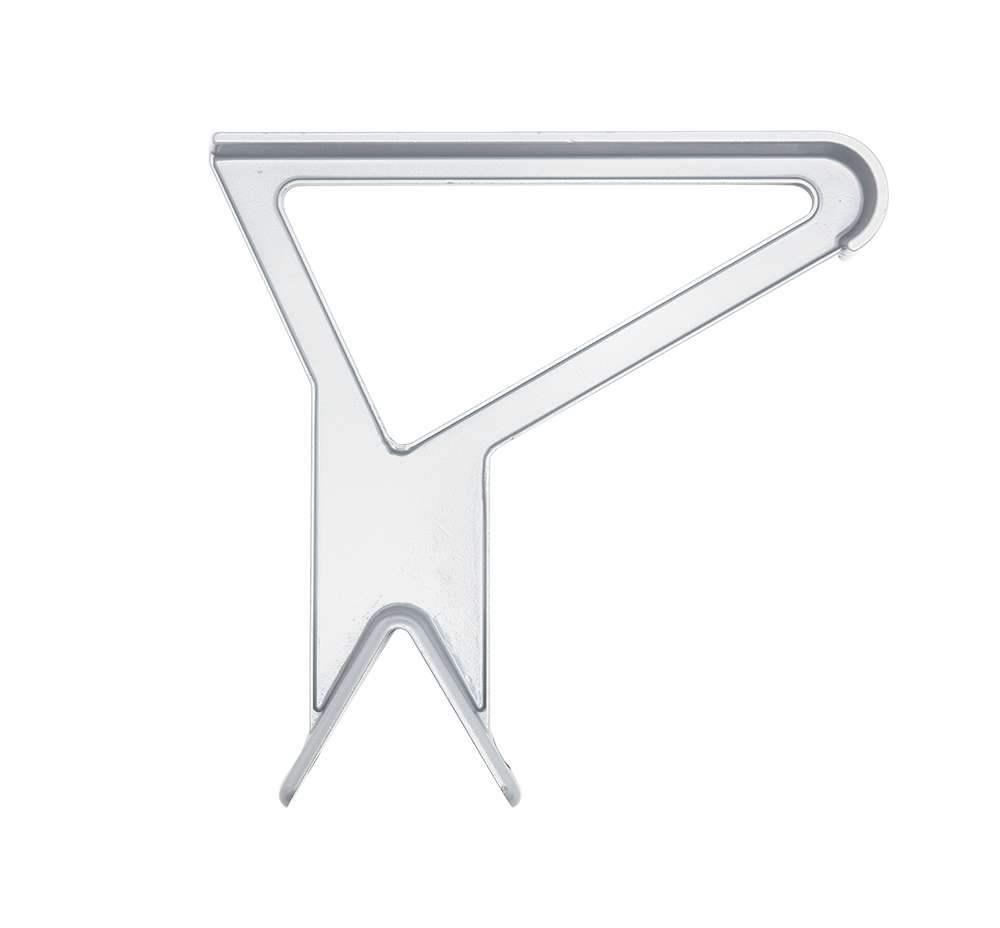

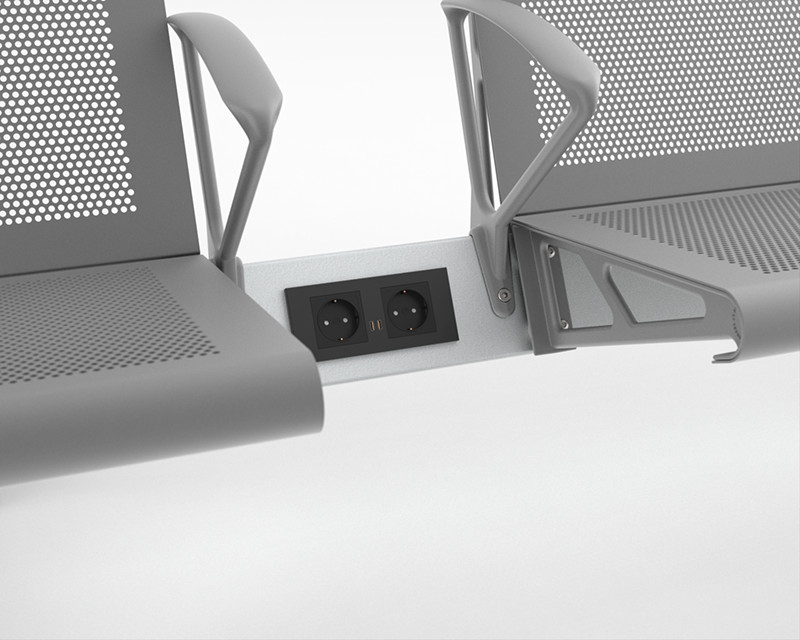

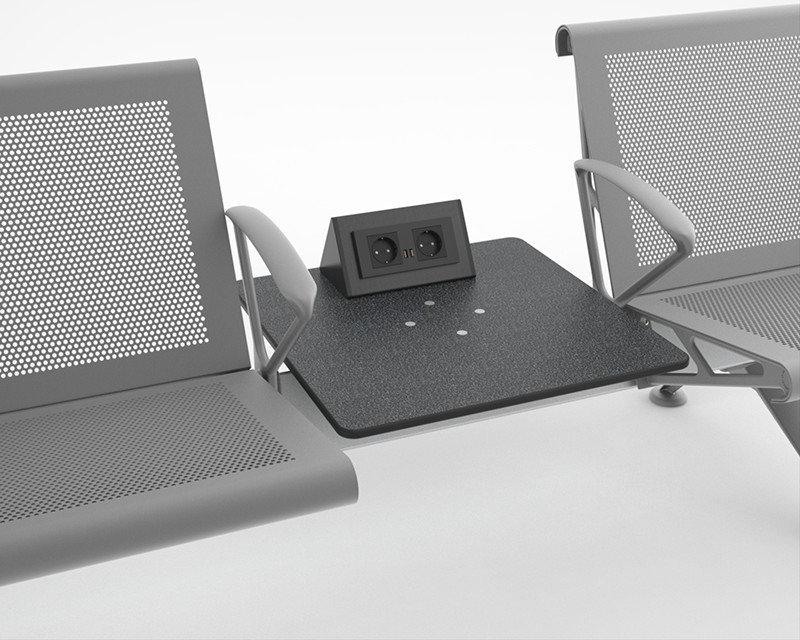

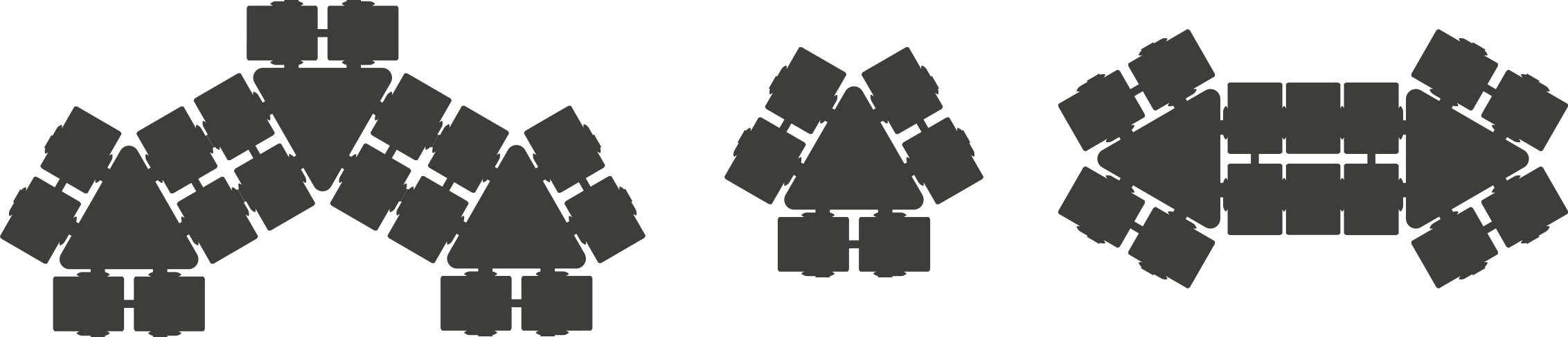

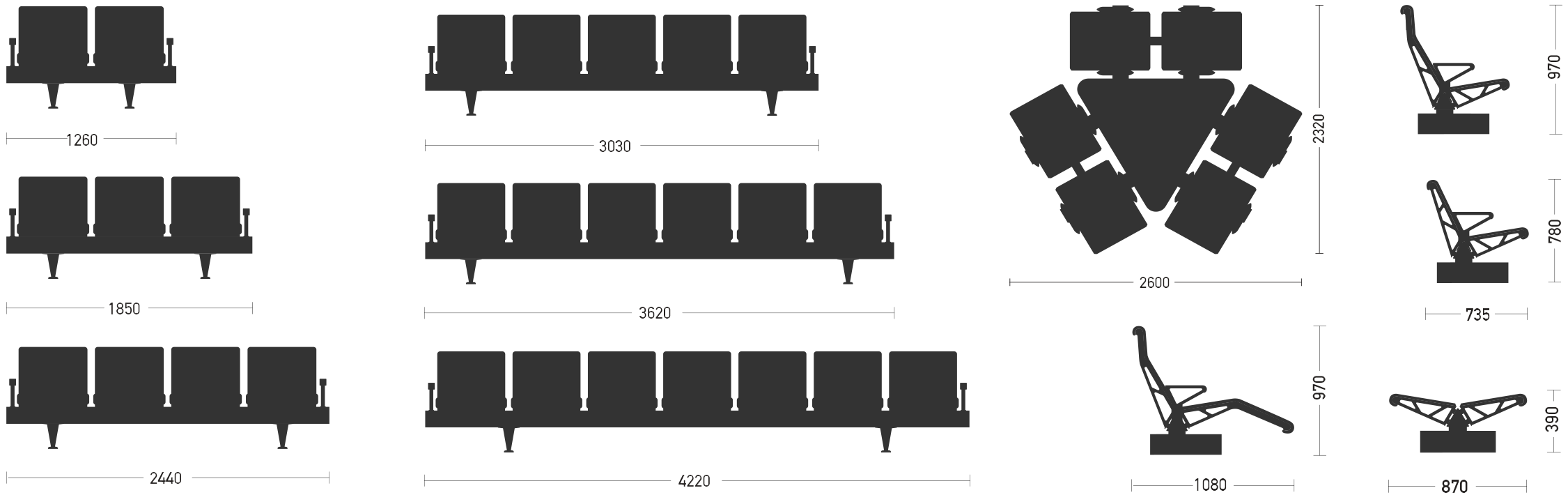

Interchangeable components are mounted on an extruded aluminium beam allowing the operator infinite flexibility before and after installation. With our widest range of seat finishes and accessories, Trax has been designed to satisfy every brief.

Configurator

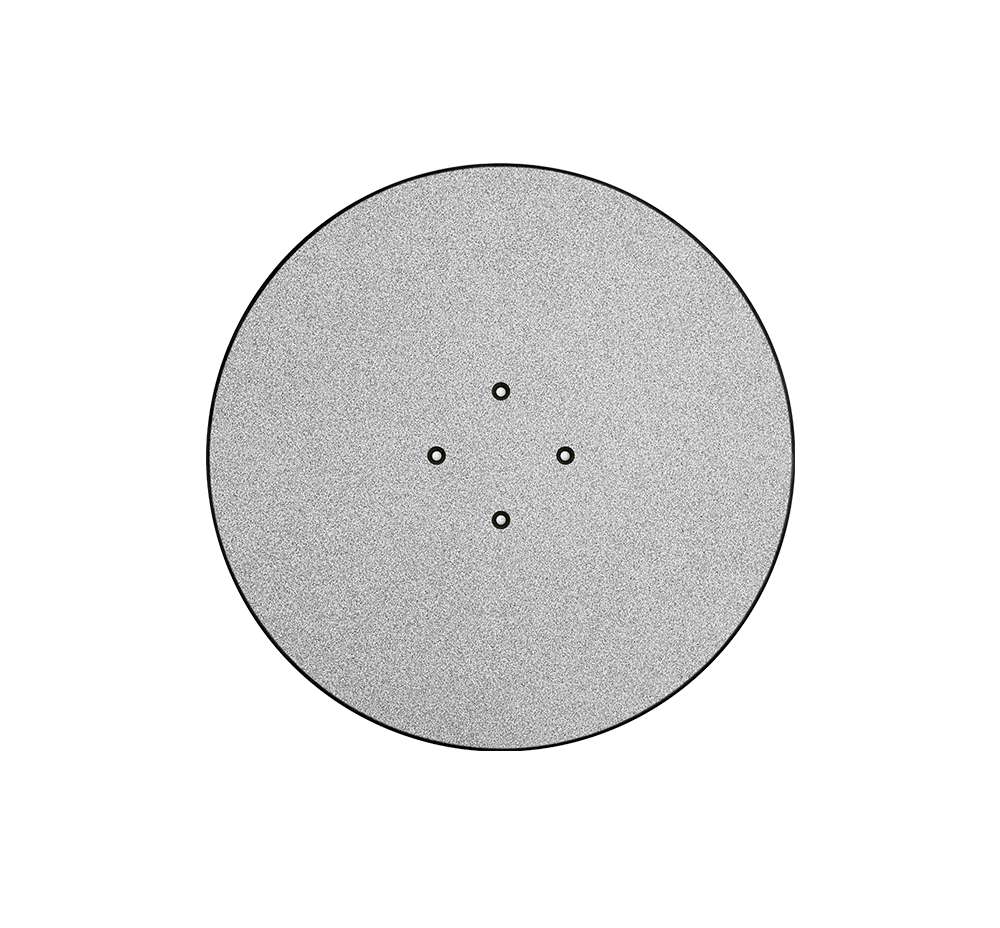

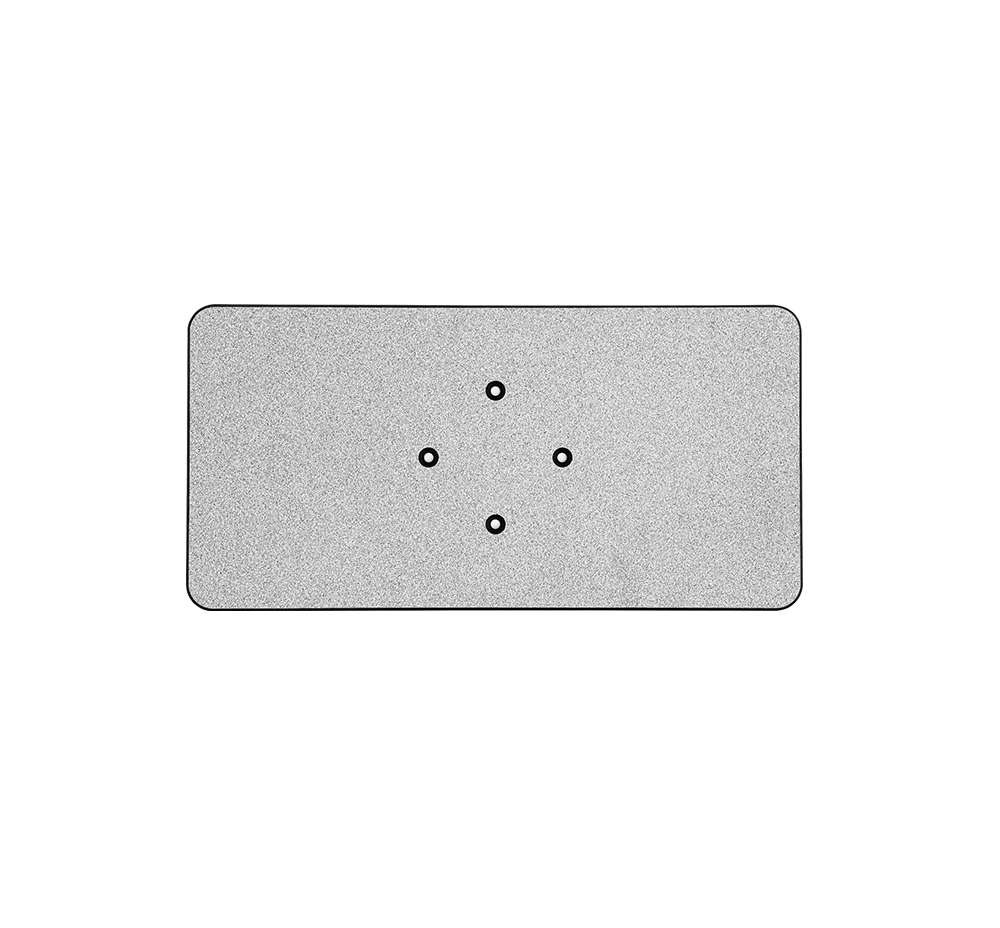

Create your ideal Trax system by selecting your chassis, finish, and accessory options. Colour palettes for all finishes are available on request. Please see the Flite and Seville pages for other configurators, and contact us if you need assistance, or have a special request.